Laser marking machine is often called laser marking machine, laser marking machine and laser marking machine. According to its working mode, it can be divided into optical fiber laser marking machine, CO2 laser marking machine, UV laser marking machine and so on. The principle of laser marking is to use the laser beam to evaporate the surface material to expose the deep material, or cause the chemical and physical changes of the surface material to carve traces, or burn part of the material through light energy to show the graphics and characters to be etched.

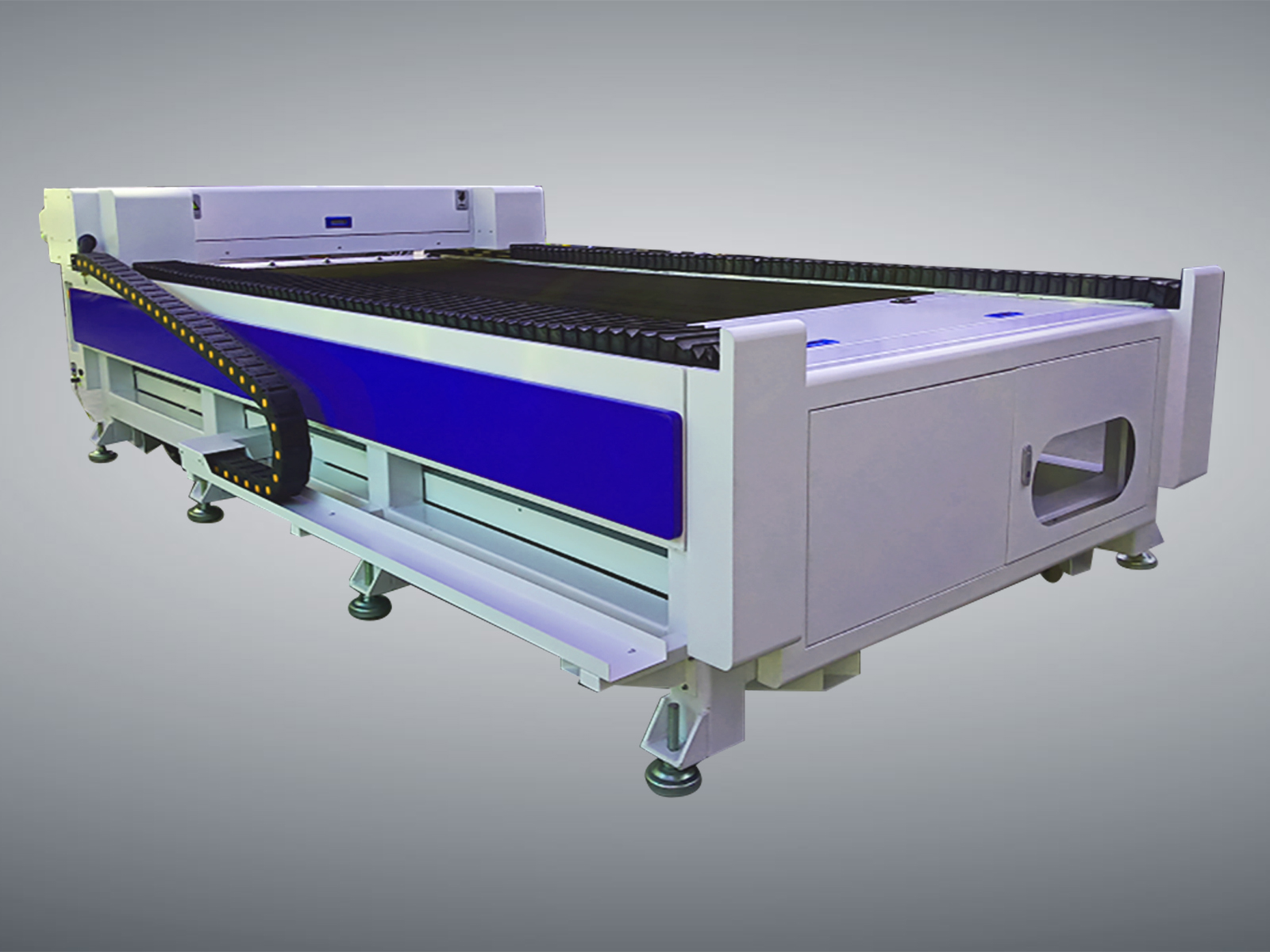

Laser engraving machine, also known as laser engraving machine, is a scientific and technological equipment that uses laser to engrave the materials that need to be engraved. Laser engraving machine is different from mechanical engraving machine and other traditional manual engraving methods. What is the difference between the mechanical equipment used in laser engraving? Now let's take a look at the difference between laser engraving machine and laser marking machine in laser engraving processing!

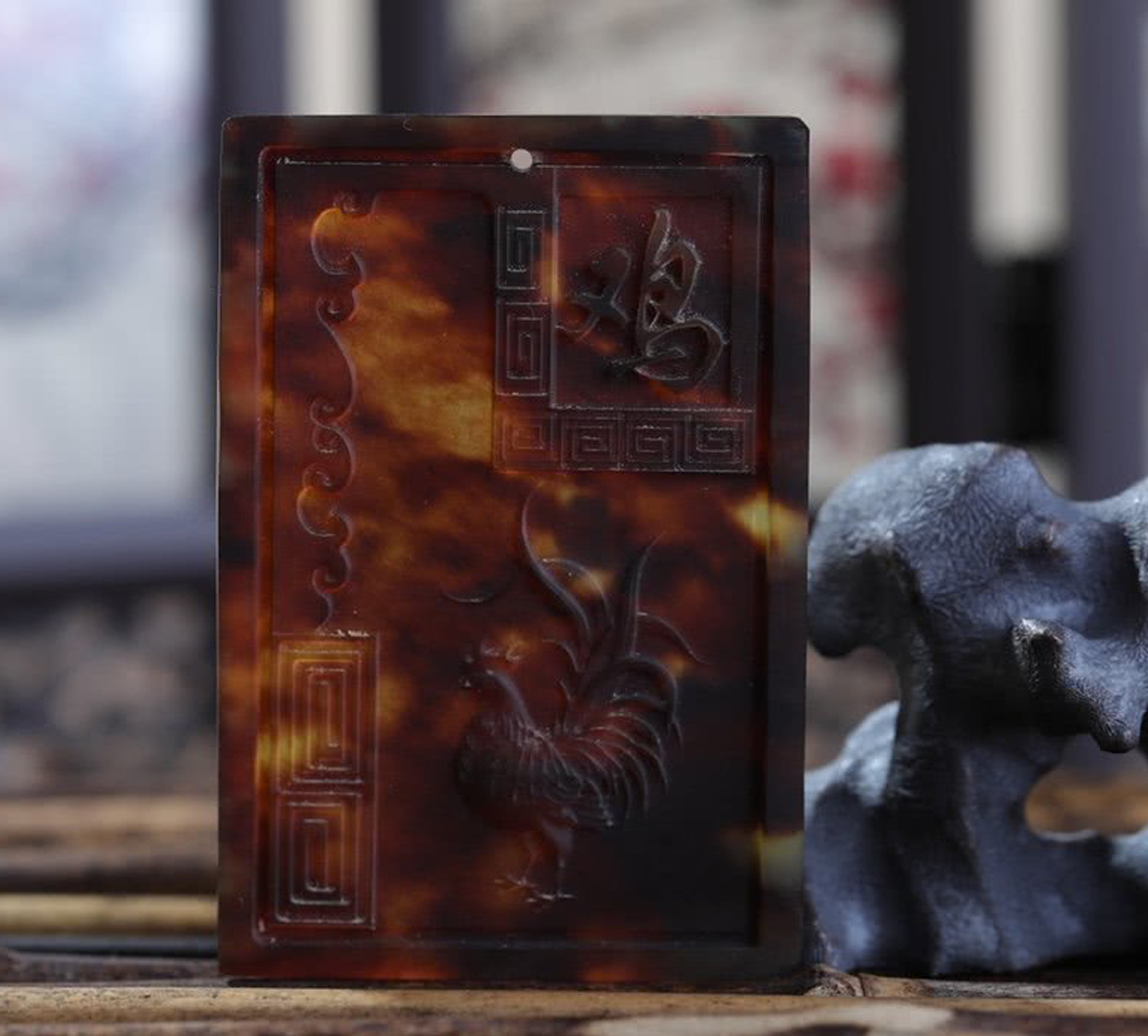

一、 The depth of processing and printing is different. Generally, the depth of laser engraving machine is relatively deep and the power is relatively large. The laser power ranges from 25W to 150W. The depth of carving materials also ranges from 0.1mm to 80mm. The carving depth depends on the specific materials. Generally, wood products, sponges, acrylic and other materials are deeply carved. The general printing depth of laser marking machine is less than 5mm, and the laser rate is between 10W and 100W.

二、Different processing speeds, the engraving speed of laser engraving machine is generally 200mm / s faster than cutting speed and 500mm / s faster than engraving speed; The speed of laser marking machine is generally three times that of laser engraving machine. In terms of speed, the laser marking machine is faster than the laser engraving machine. Like mineral water manufacturers, the assembly line in one minute is about 100 meters.

三、The precision and speed of the marking machine are much higher than those of the engraving machine. The laser can act on the material surface with a fine beam, and the thin line width can reach 0.02mm. It creates a broad application space for precision machining and increasing anti-counterfeiting function.

四、Difference of marking format: generally, the marking format of laser marking machine is 200 * 200mm, and the engraving machine can carve large format. Laser marking machine uses galvanometer scanning, so the working format is relatively small. To put it bluntly, the laser engraving machine is to replace the main shaft of an engraving machine with a laser focusing lens and use the laser instead of the tool for processing. Therefore, as long as the XYZ axis is large enough, you can process as much as you want to process, but the accuracy and processing efficiency are greatly affected by machinery. In addition, because there is no galvanometer, focusing lens and other optical path systems, it is better to cool, so the laser power output is not limited.

五、Difference of lasers: the optical path system of laser engraving machine is composed of three reflective lenses and a focusing mirror. The laser is generally a carbon dioxide glass tube. The service life of glass tube laser is generally within 2000-10000 hours. Carbon dioxide glass tube lasers are disposable. The lasers of laser marking machines are generally metal tube lasers (non-metallic marking machines) and YAG solid-state lasers (metal laser marking machines), with a service life of more than five years. The metal tube of the laser marking machine can be inflated again.

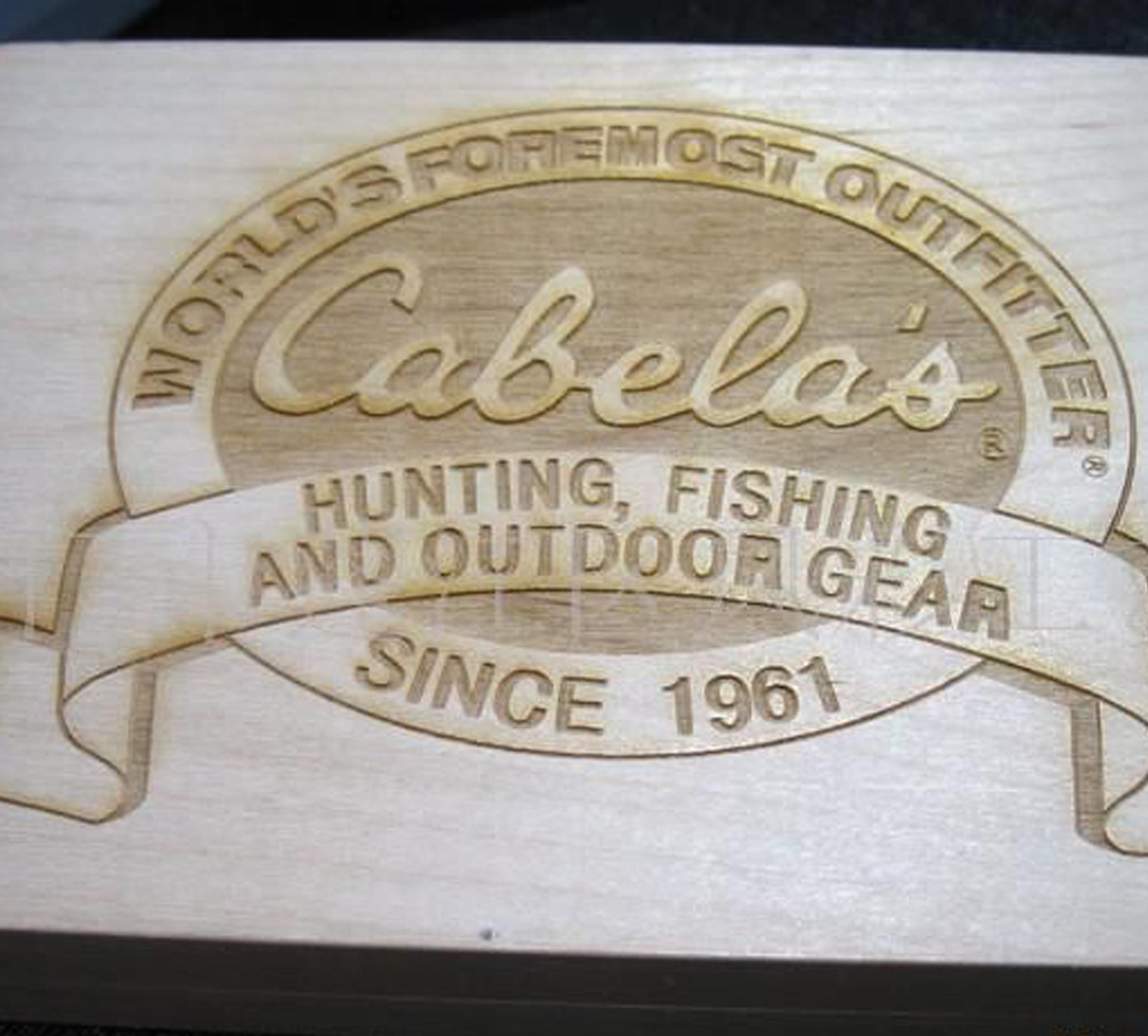

六、The difference of engraving and marking materials and the diversification of engraving materials by laser engraving machine: glass, crystal, acrylic, wood, marble, cloth, leather, felt, paper, PVC, plastic, mosaic and other non-metallic materials can be carved or cut. The application of laser marking machine is mainly for cloth, leather, wood products, ceramics or metal products.