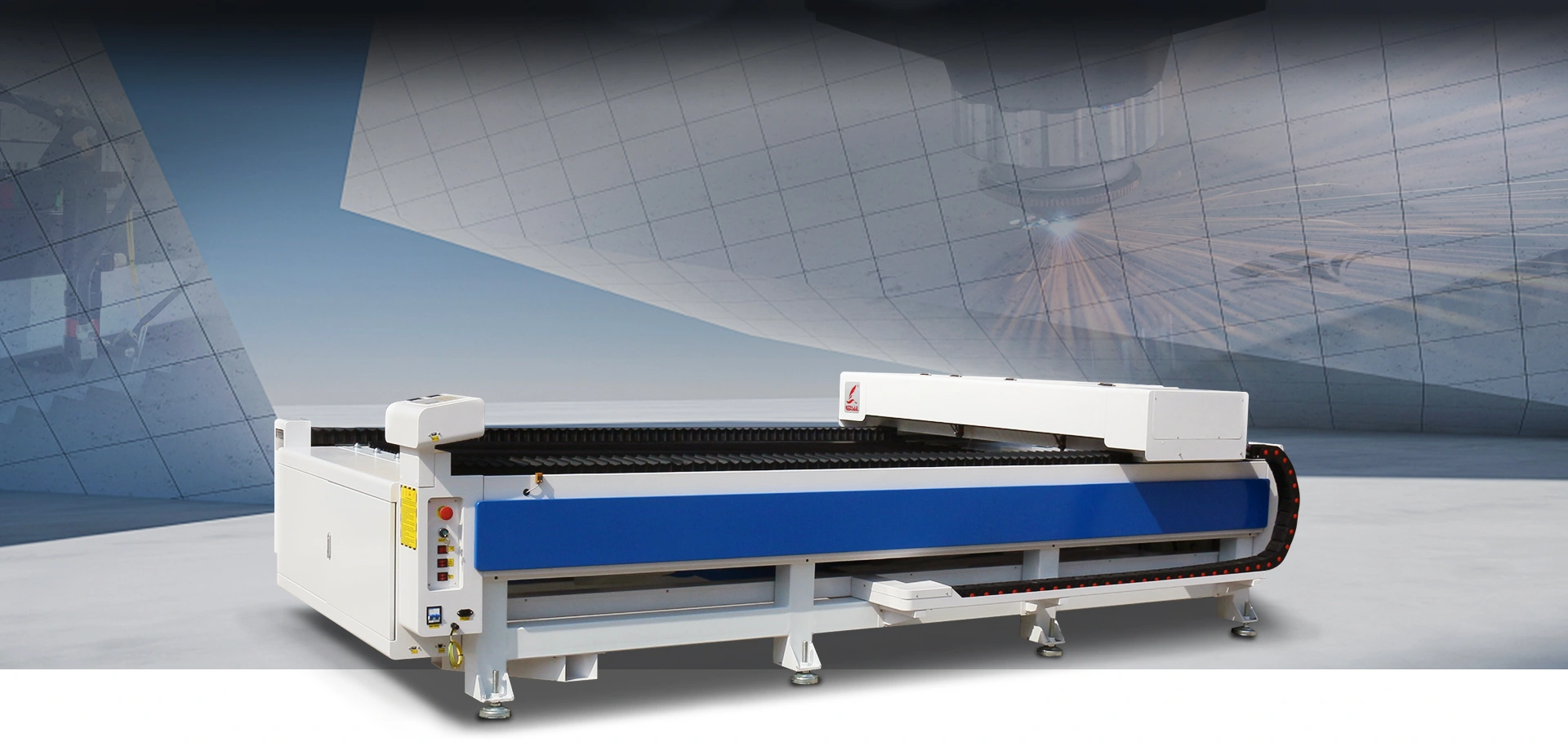

The 1325 laser cutting machine (1300mm x 2500mm work area) is one of the most popular industrial-grade CO2 lasers—but is it the best fit for your specific needs? This guide breaks down key decision factors to help you determine if this powerhouse machine aligns with your production requirements.

Key Considerations Before Buying a 1325 Laser Cutter

1. Assess Your Production Needs

-

✅ Ideal for:

-

Large-format cutting (full 4x8 ft sheets)

-

High-volume orders (500+ cuts per week)

-

Thick materials (15-25mm wood, 10-20mm acrylic)

-

-

❌ Not ideal for:

-

Small workshops with limited space

-

Businesses that only engrave (smaller lasers are cheaper)

-

Heavy metal cutting (fiber lasers are better)

-

2. Space & Power Requirements

-

Floor space needed: ~10' x 6' (plus ventilation/exhaust system)

-

Electrical: Many 150W+ models require 3-phase power

-

Ventilation: Industrial fume extraction is a must

3. Budget & ROI Analysis

-

Machine cost: 15,000–60,000+ (depending on power & features)

-

Operational costs:

-

Tube replacements (~10,000-hour lifespan)

-

Maintenance (lens cleaning, alignment, cooling system)

-

-

Break-even point: Typically 6-18 months for full-time businesses

Industries That Benefit Most from a 1325 Laser

| Industry | Best Applications | Recommended Power |

|---|---|---|

| Signage & Displays | Acrylic signs, LED panels | 100W-150W |

| Furniture & Woodworking | Plywood cabinets, decorative panels | 130W-200W |

| Packaging & Prototyping | Custom boxes, foam inserts | 80W-150W |

| Automotive/Aerospace | Gaskets, interior panels, part labeling | 150W-300W (with metal marking) |

Alternatives to Consider

Smaller/Faster Options

-

6090 Laser (600x900mm) – Best for small businesses (under $10K)

-

Fiber Lasers – If you mostly cut/engrave metals

Larger/More Powerful Options

-

1530 Laser (1500x3000mm) – For extra-large sheet processing

-

High-Power RF Lasers – For thick metals & industrial applications

Final Decision Checklist

✔ Do you regularly process full 4x8 ft sheets?

✔ Is your production volume high enough to justify the cost?

✔ Do you have proper space, power, and ventilation?

✔ Will the machine pay for itself within 1-2 years?