Leather is a quality material that has been used for centuries. Leather has been used for many purposes throughout history, but is also present in modern manufacturing processes. Laser cutting is one of the many methods used to produce leather designs. Leather has proven to be a good medium for laser cutting and engraving. This paper describes a non-contact, fast and highly accurate laser system for cutting leather.

With the progress of society and the development of science and technology, leather products are being used more and more widely. Leather products play an indispensable role in daily life, such as clothing, shoes, bags, wallets, gloves, sandals, leather hats, belts, watch straps, leather mats, car seats and steering wheel covers. Leather products are creating unlimited commercial value.

Increased popularity of laser cutting

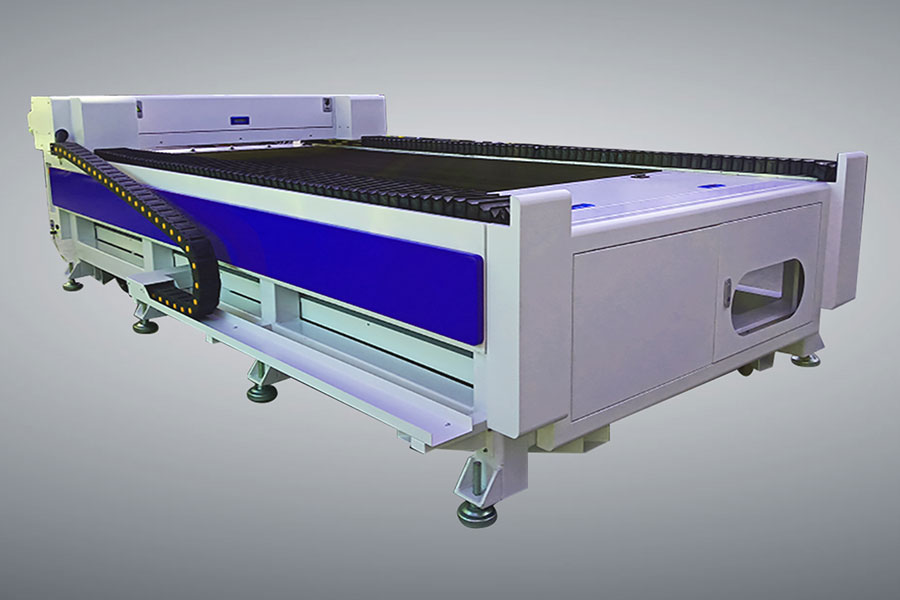

In recent years, the use of leather laser cutting machines has also emerged at this time due to the widespread use and popularity of lasers. The high energy, high power density carbon dioxide (CO2) laser beam allows for fast, efficient and continuous processing of leather. The laser cutting machine uses digital and automated technology to provide the leather industry with the ability to hollow out, engrave and cut.

The advantages of using CO2 laser cutting machines in the leather industry are obvious. Compared to traditional cutting methods, laser cutting offers the advantages of low cost, low consumption, no mechanical stress on the workpiece, high accuracy and high speed. Laser cutting also offers the advantages of safe operation, simple maintenance and continuous processing.

Laser cutting of leather

The working principle of laser cutting

The CO2 laser beam is focused into a small spot so that the focal point reaches a high power density, rapidly converting photon energy into heat to the point of vaporisation and forming a hole. As the beam moves through the material, the hole creates a continuous narrow cutting seam. This cut seam is minimally affected by residual heat and therefore no distortion of the workpiece occurs.

Laser cut leather is consistent and accurate in size and the cut can be of any complex shape. The use of computer graphics for pattern design allows for high efficiency and low cost. Thanks to this combination of laser and computer technology, the user's design on the computer allows for laser engraving output and changes to the engraving at any time.

The account manager of a shoe factory abroad in Lesse says that the company used to cut shoe moulds and engrave patterns using a moulding knife, requiring a different mould for each style. The operation was very complicated and could not handle small and complex pattern designs. Since purchasing a laser cutting machine from Wuhan Golden Laser Co Ltd, laser cutting has completely replaced manual cutting. Now, the laser cutting machine produces more exquisite and beautiful leather shoes, and the quality and workmanship has been greatly improved. It has also greatly improved production efficiency and is particularly suitable for small orders or sometimes customised products.

Leather laser cutting

The leather industry is undergoing a technological change, with dedicated laser leather cutting machines breaking the low speed and nesting difficulties of traditional manual and electric shears, and comprehensively addressing the problems of inefficiency and material waste. In contrast, laser cutting machines are fast and easy to operate, requiring only the input of graphics and dimensions into a computer. The laser cutter cuts the entire material into a finished product without the need for tools and dies. Non-contact processing is simple and quick with laser cutting.

The CO2 laser cutting machine can perfectly cut leather, synthetic leather, polyurethane (PU) leather, artificial leather, suede, brushed leather, microfibre, etc.

Laser cutting machines enable a wide range of applications. CO2 lasers can cut and engrave textiles, leather, Plexiglas, wood, MDF and other non-metallic materials. In shoe materials, the precision of laser cutting machines makes it easier to produce complex designs than manual cutting. As the laser evaporates and burns the material to make the cut, fumes will inevitably be generated, so the machine needs to be placed in a well ventilated area with a dedicated exhaust system.